The method using cement-based mortar or concrete had been mainstream in conventional fireproofing work. However, there has been a growing trend recently for materials with "lighter weight" and "higher performance." We therefore respond to customer needs through consolidation of a consistent engineering system from fireproofing design to research on materials and methods in partnership with the world's leading fireproofing manufacturers.

FIREPROOFING

- TOP

- Business Field

- Thermal Insulation

- FIREPROOFING

Plants handling hazardous materials such as petroleum and liquefied gas are obligated to perform fireproofing work for steel frame structures to prevent collapse due to fire. For example, fireproofing is mandatory for pipe racks, equipment skirts, cable trays, Spherical tank columns in petroleum refining, petrochemical and liquefied gas plants and also offshore oil rig facilities.

-

01

Fire Heater Module Skid Structure (Pyrocrete)

-

02

Fire Heater Module Skid Structure (Pyrocrete)

-

03

Oil Rig Fire Wall (Epoxy)

-

04

Spherical Tank Columns (Mortar Fireproofing)

-

05

Structure (Mortar Fireproofing)

Waterproofing materials are used by kneading Portland cement, aggregate (sand) and water at a specified mixture ratio and applying it by troweling or spraying.

Product Name of Refractory Material | Partner Manufacturer |

|---|---|

Pyrocrete 241 This is a lightweight cement-based fireproofing material which has a long successful track record as a fireproofing material for outdoor steel frame structures in industrial plants and marine structures. |

Carboline Company (U.S.A) |

Thermolag 3000 This product, which is an epoxy-type fireproofing material, is used to protect human life and facilities. In addition, its excellent anticorrosion function continues to protect expensive facilities from corrosion even in daily operations outside of fire protection. |

Carboline Company (U.S.A) |

Mandoseal, Fendolite MⅡ |

Mandoval LTD. (U.K) |

-

KEY POINTS

-

SERVICE PLAN

We respond to customer needs from design and construction to maintenance under optimum conditions, employing a workable system with experienced staff using reliable technologies.

-

BUSINESS SYSTEM

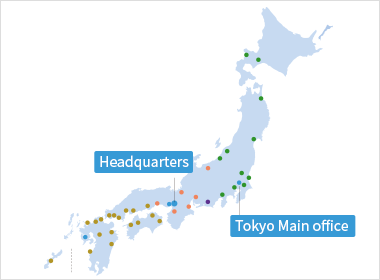

Mainly Headquarters in Osaka and Main office in Tokyo are developing business from Hokkaido in the north to Okinawa in the south, promptly responding by a broad network and reliable technologies.