LNG Carrier

Liquefied natural gas (LNG) and liquefied petroleum gas (LPG), recognized as clean energy sources, liquefy when they are cooled at a cryogenic temperature or when moderate pressure is applied to them. Accordingly, any carelessness in cold insulation work will result not only in an increase in boil-off gas but also in lower transportation efficiency. We have achieved world-class results in a series of cold insulation work related to LNG and LPG, from on-site liquefaction equipment to low-temperature liquefaction carriers and domestic storage facilities, by using our long-cultivated cryogenic cold insulation technology.

A carrying vessel with aluminum spherical tanks supported on the cylindrical structure called the skirt and installed to the vessel’s body.

LNG Carrier

LPG Carrier

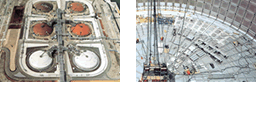

Utilizing thermal insulation technology in cryogenic areas including ethylene facilities, LNG shipments and receiving terminals as well as our wealth of installation experience, we have advanced research and development of the Moss type spherical tank insulation system since 1970.

LNG evaporation is reduced by insulation panels of a two-layer structure.

Insulation Panel

General View of Moss Type

Spherical Tank Insulation

General View of

Press ure-Acumulation

As characteristics of the panel system, phenol foam which resists cracking due to small thermal expansion has been adopted for the low temperature side while the insulation panel molded integrally with polyurethane foam which has self adhesiveness with low thermal conductivity has been adopted for the normal temperature side. In addition, polyurethane foam is injected into the joints between each panel for formation on-site to integrate the whole tank insulation. With this, the panel system offers outstanding insulation performance.

A shield to prevent LNG spillage from valves or pumps installed within the LNG terminal.

01 Production |

Liquefaction plant For LNG, natural gas mined from underground is liquefied by cooling it to -162°C or applying pressure to it. As a result, the volume of liquefied natural gas becomes one six-hundredth of the gas state which brings about advantages in mass transportation and storage. | |

|---|---|---|

02 Shipment |

Shipment facilities Gas liquefied by cooling it to a cryogenic temperature is shipped carefully. | |

03 Carrying |

LNG/LPG carrier LNG and LPG are transported by sea to consuming regions by carriers. Tank insulation is important for low-temperature liquefied gas (LNG, LPG) carriers, and our insulation technology minimizes the evaporative (boil-off) loss of liquefied gas. |

|

04 Receiving facilities |

Receiving facilities These facilities are used to unload LNG from the landed LNG carrier. |

|

05 Storage |

Storage LNG is stored in tanks in a liquid state. Our thermal insulation technology is used for both aboveground and underground tanks. |

|

06 Delivery |

Vaporizing facilities These facilities are used to restore LNG to natural gas by vaporizing it.After adjustment of the heat amount, gas is supplied as city gas or fuel for power generation. | |

In our Central Laboratory, cryogenic tests are carried out according to various applications such as insulation panels and pipe covers.