FURNACE & REFRACTORY

- TOP

- Business Field

- Thermal Insulation

- FURNACE & REFRACTORY

Facilities operated under extremely high temperatures such as industrial furnaces, incinerators and boiler ducts require installation of refractory lining materials to protect against heat and increase combustion efficiency. We have worked toward development of our own unique technologies and construction methods to meet ever-increasing needs for sophistication and diversification.

-

01

Brick work for inner furnace surfaces

Porous burned bricks are used. Insulating refractory materials which have superior heat insulating properties of heat insulating bricks are applied in addition to strength and fire resistance of fire bricks in this method. -

02

Application of Ceramic Fibers and Castable Materials for Inner Furnace Surfaces

General-purpose refractory materials used in industrial furnace linings or incinerators are applied. -

03

Ceramic Fiber Linings Being Installed

As characteristics, heat resistance performance and thermal shock properties are superior.

-

KEY POINTS

The method using cement-based mortar or concrete had been mainstream in conventional fireproofing work. However, there has been a growing trend recently for materials with "lighter weight" and "higher performance." We therefore respond to customer needs through consolidation of a consistent engineering system from fireproofing design to research on materials and methods in partnership with the world's leading fireproofing manufacturers.

-

SERVICE PLAN

We respond to customer needs from design and construction to maintenance under optimum conditions, employing a workable system with experienced staff using reliable technologies.

-

BUSINESS SYSTEM

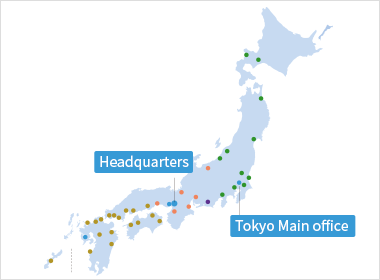

Mainly Headquarters in Osaka and Main office in Tokyo are developing business from Hokkaido in the north to Okinawa in the south, promptly responding by a broad network and reliable technologies.